Trochoidal milling

Trochoidal milling is a processing method that deals with some abrupt changes in the local large margin of the three-dimensional surface. Figure 6-31 is a schematic diagram of trochoidal milling. This milling method is completed in response to the depth of cut of the cutter caused by the "surrounding" of the solid material on the tool in the milling of the three-dimensional surface.

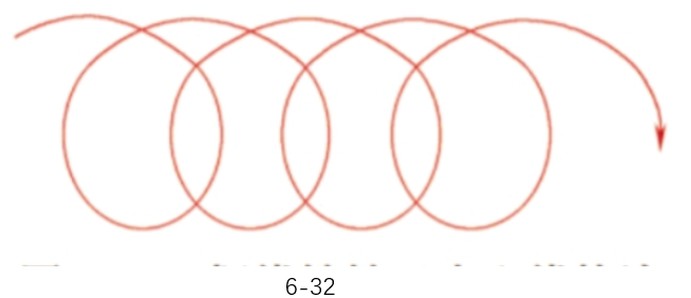

Similar to trochoidal milling, sheet milling is also designed to quickly remove the part of the stock with a large margin. The conventional milling contact center angle of the inner fillet is very large, and the center angle of the tool contact is too large. During trochoidal milling, the tool is generally forward, but sometimes the tool is backward, and the axis of the tool is still swinging laterally, and the movement trajectory of the center line of the trochoidal milling cutter is shown in Figure 6-32. In areas where machining conditions are poor, the allowance can be quickly removed by trochoidal milling, while in other parts the cutter can be machined using conventional cutting methods. Figure 6-33 is a typical part suitable for trochoidal milling. In these areas, if only conventional machining methods are used, the force on the milling cutter is uneven, or machining hours are wasted by using multiple full passes. With trochoidal milling, these problems can be effectively solved. Generally speaking, the swing width of the centerline of the milling cutter is 0.2~1 times the diameter of the milling cutter. In other words, when cycloidal milling is performed, the width of the processing is between 1.2 ~ 2 times the diameter of the milling cutter. It is recommended that the amount of forward movement of the milling cutter axis during trochoidal milling is 0.2~0.8 times of the diameter of the milling cutter during trochoidal milling.

Sheet skin milling

Slice milling (see Figure 6-34) is also known as peeling milling or slice milling. The cutting form of some peel milling is similar to that of Peking duck, or similar to that of Shanxi knife noodles. It is usually twice the normal cutting speed, and the cutting width (radial depth of cut) is small (mostly 1%~ 10% of the diameter of the milling cutter), and it is larger and has a heavy load (see Figure 6-34c). When the method of sheet milling is adopted, through the layer by layer cutting of multiple local thin cutting layers, the radial cutting force is low, the stability requirements are not high, and the large cutting depth can be allowed.

Dynamic milling

Dynamic milling is a machining method based on a constant material removal rate. Figure 6-35 is a typical artifact. Figure 6-36 shows the conventional programming path and the dynamic programming path of dynamic milling. On the one hand, traditional programming has too many empty tool paths at the linear frame, resulting in a waste of processing time; On the other hand, the fillet is overloaded, resulting in a high breakage rate of the tool in this area. Dynamic milling arranges multiple passes at the fillets, while passing through the straight frame segments quickly. Generally speaking, the traditional conventional programmed feed speed is fixed, and the tool lifts more; Dynamic milling, on the other hand, fixes the material removal rate for minimum air cutting paths and maximum machining efficiency. According to GibbsCAM, this machining method is mainly used for end mills, where the cutting speed and depth of cut are fixed, and the constant cutting width and feed rate are automatically selected by the program based on the material removal rate. Through this method, intelligent CNC code is realized, and does not rely on the high-speed milling function of the machine tool itself; It uses less code length and more arc motion; Avoid the use of multiple tools in the roughing process; Optimized toolpaths to reduce machining times: Variable step-through cutting is realized, which increases cutting efficiency. Cycloidal milling, sheet milling, and dynamic milling all rely on computer-aided manufacturing (CAM) systems to complete, and only the ideas are introduced here.