Tool related points

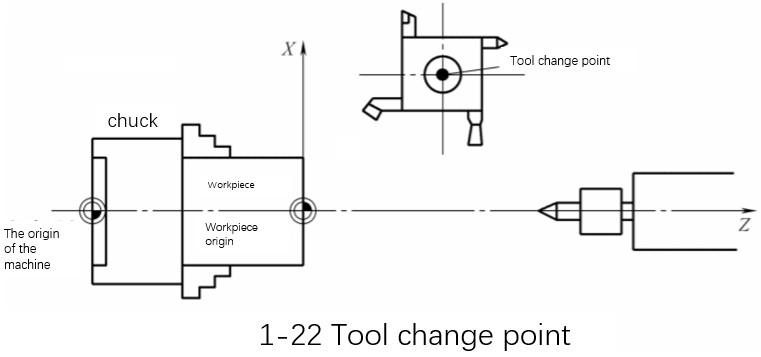

1. Knife position

The position of the tool on the machine is indicated by the position of the "tool point". The so-called tool position point refers to the positioning reference point of the tool. Different tools have different tool positions, and for turning tools, the tool positions of various types of turning tools are shown in Figure 1-21.

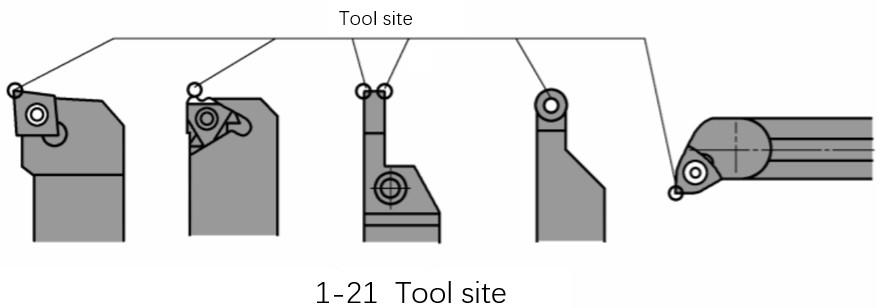

2. Tool alignment point

The tool setting point is the starting point of the tool's motion relative to the workpiece in CNC machining, and can also be called the starting point of the program or the starting point. With the tool point, the mutual position relationship between the machine coordinate system and the workpiece coordinate system can be determined. The tool setting point can be selected on the workpiece or outside the workpiece (e.g. on a fixture or machine), but it must have a certain dimensional relationship with the positioning datum of the workpiece. Figure 1-22 shows the tool setting point of a turned part. The principle of tool setting point selection is: easy alignment, convenient programming, small tool setting error, convenient and reliable inspection during processing.

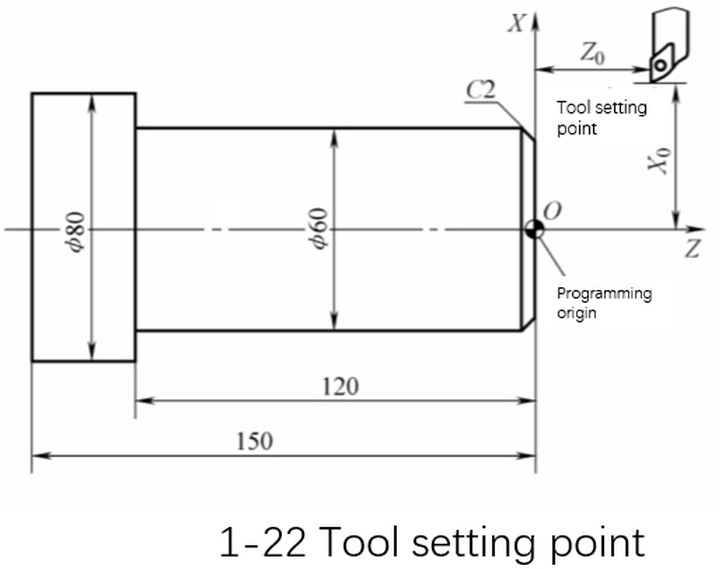

3. Tool change point

The tool change point is the point at which the part is machined or the tool is changed during the machining process (Figure 1-23). The purpose of setting up a tool change point is to keep the tool in a relatively safe area when changing the tool, the tool setting point can be far away from the workpiece and tailstock, or anywhere where the tool change is convenient, but there must be a definite coordinate relationship between the point and the program origin.