Basic knowledge of CNC machine tool fixtures

Machine tool fixture refers to a device installed on a machine tool to clamp a workpiece or guide a tool, so that the workpiece and the tool have a correct mutual position relationship.

1. The composition of the CNC machine tool fixture

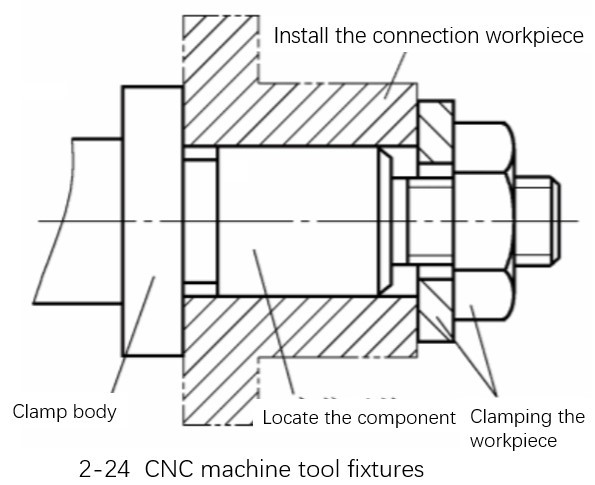

As shown in Figure 2-24, the CNC machine tool fixture can usually be composed of several parts such as positioning elements, clamping elements, mounting connecting elements and clamping bodies according to its functions and functions.

The positioning element is one of the main positioning elements of the fixture, and its positioning accuracy will directly affect the machining accuracy of the workpiece. Commonly used positioning elements are V-blocks, positioning pins, positioning blocks, etc. The function of the clamping element is to maintain the original position of the workpiece in the fixture, so that the workpiece will not change the original position due to external force during machining.

The mounting connection element is used to determine the position of the fixture on the machine and thus to ensure the correct machining position between the workpiece and the machine.

2. The basic requirements of CNC machine tool fixtures

(1) Accuracy and stiffness requirements CNC machine tools have the characteristics of multi-profile and continuous machining, so the requirements for the accuracy and stiffness of CNC machine tool fixtures are also higher than those of general machine tools, which can reduce the positioning and clamping error of the workpiece on the fixture and the deformation error of rough machining.

(2) Positioning requirements The workpiece should generally be completely positioned relative to the fixture, and the datum of the workpiece should have a strict determined position relative to the origin of the machine tool coordinate system, so as to meet the requirements of the correct movement of the tool relative to the workpiece. At the same time, the fixture should also be completely positioned on the machine tool, and each positioning surface on the fixture should have an accurate coordinate size relative to the coordinate system origin of the CNC machine tool, so as to meet the requirements of simplified positioning and installation of the CNC machine tool.

(3) Openness requirements: CNC machine tool processing is automatic feed processing of tools. The fixture and workpiece should provide a relatively spacious running space for rapid movement of the tool and quick actions such as tool change. Especially for multi-tool and multi-process processing that needs to enter and exit the workpiece many times, the structure of the fixture should be as simple and open as possible, so that the tool is easy to enter and prevent collision with the fixture workpiece system during the tool movement. In addition, the openness of the fixture is also reflected in the smooth chip evacuation and easy chip removal. (4) Quick clamping requirements In order to meet the needs of efficient and automated processing, the fixture structure should adapt to the needs of fast clamping, so as to minimize the auxiliary time of workpiece clamping and improve the utilization rate of machine tool cutting operation.

3. Classification of machine tool fixtures

There are many types of machine tool fixtures, which can be divided into the following categories according to their generalization. (1) Universal fixtures Self-centering chucks, single-action chucks, centers, etc. are all universal fixtures, and this kind of fixtures have been standardized. It is characterized by strong versatility and simple structure, and there is no need to adjust or slightly adjust the workpiece when clamping

To be used for the production of small batches of single pieces. (2) Special fixture: The special fixture is specially designed for a certain process of a certain part, which is characterized by compact structure, fast operation and convenience. However, the design and manufacture of this kind of fixture has a large workload, long cycle and large investment, and its economic benefits can only be fully utilized in mass production. There are two types of special clamps: structurally adjustable and structurally non-adjustable.

(3) Group fixture Group fixture is produced with the development of group processing technology, it is according to the group processing technology, the workpiece is grouped according to the shape size and the commonality of the process, and is specially designed for each group of similar workpieces. It is characterized by clear use objects, compact structure and easy adjustment.

(4) Combined fixture The combined fixture is a special fixture assembled from a set of pre-manufactured standard components. It has the advantage of a special fixture, which can be disassembled and stored after use, which shortens the production preparation cycle and reduces the processing cost. Therefore, the combination fixture is suitable for both single-piece and medium- and low-volume production, as well as for high-volume production.